Automatic Folding Carton Sealing Machine

- backpack

- china guangdong foshan

- 2024

- 1000

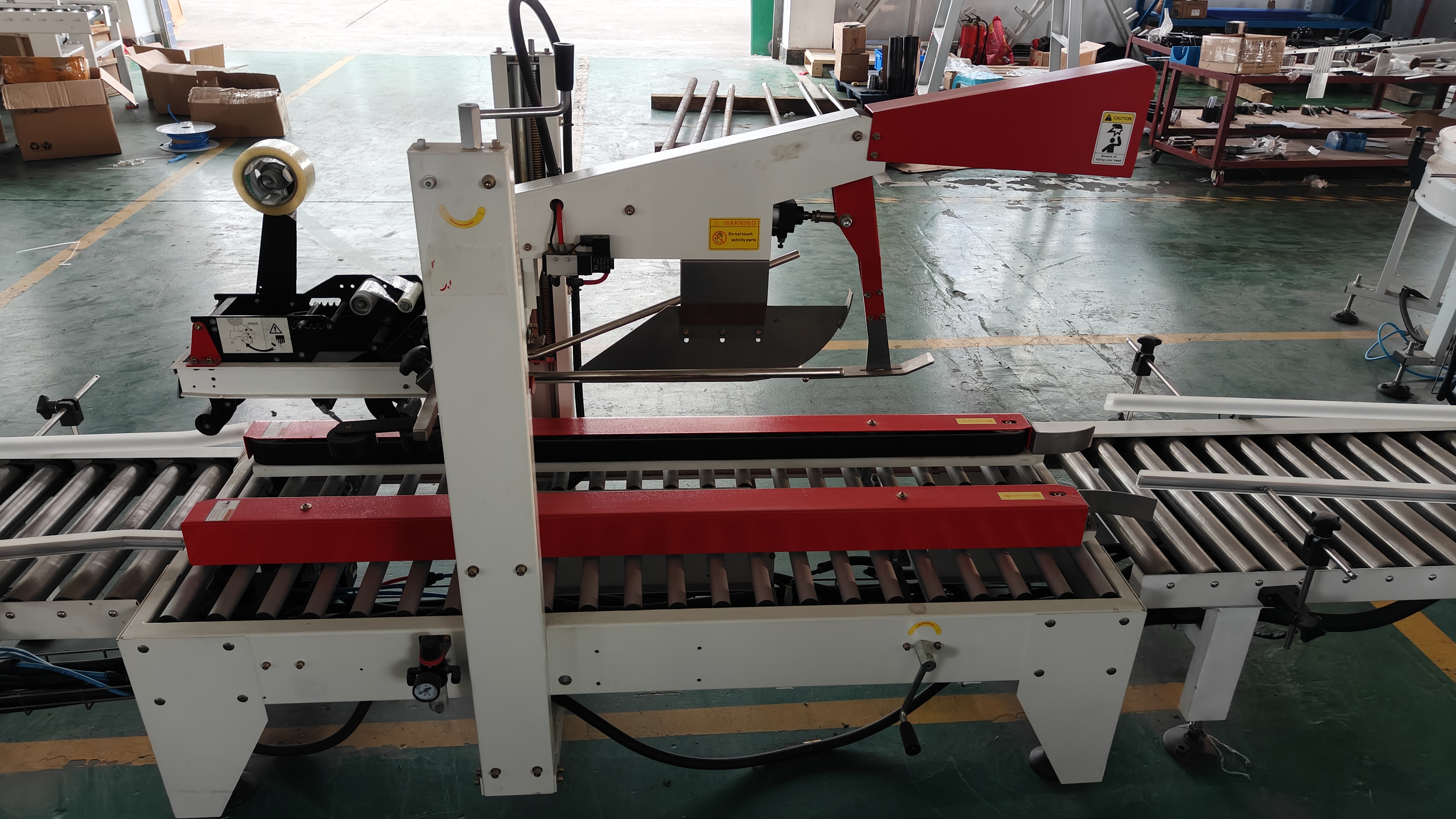

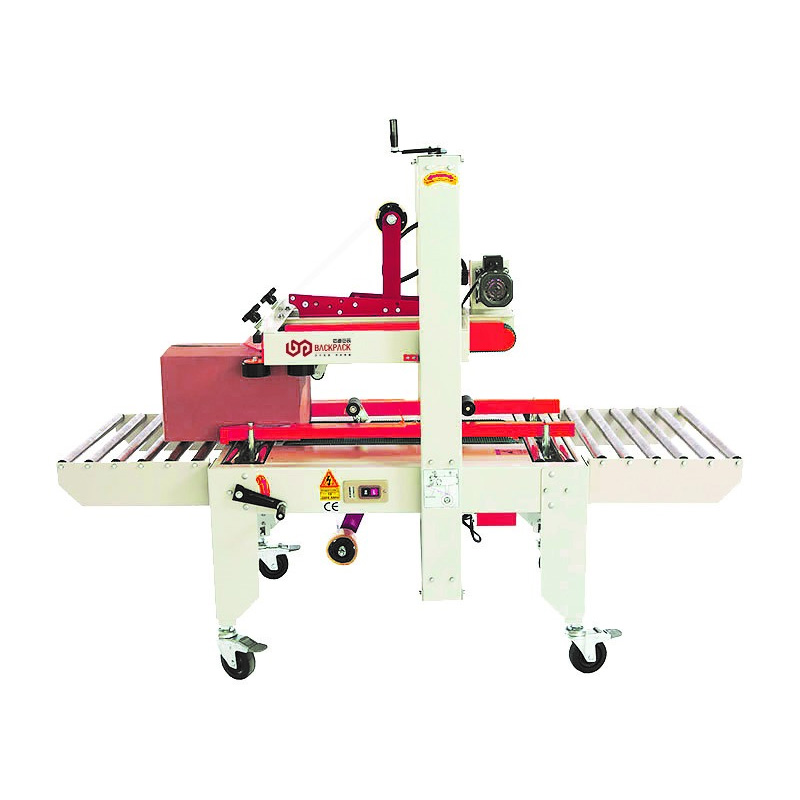

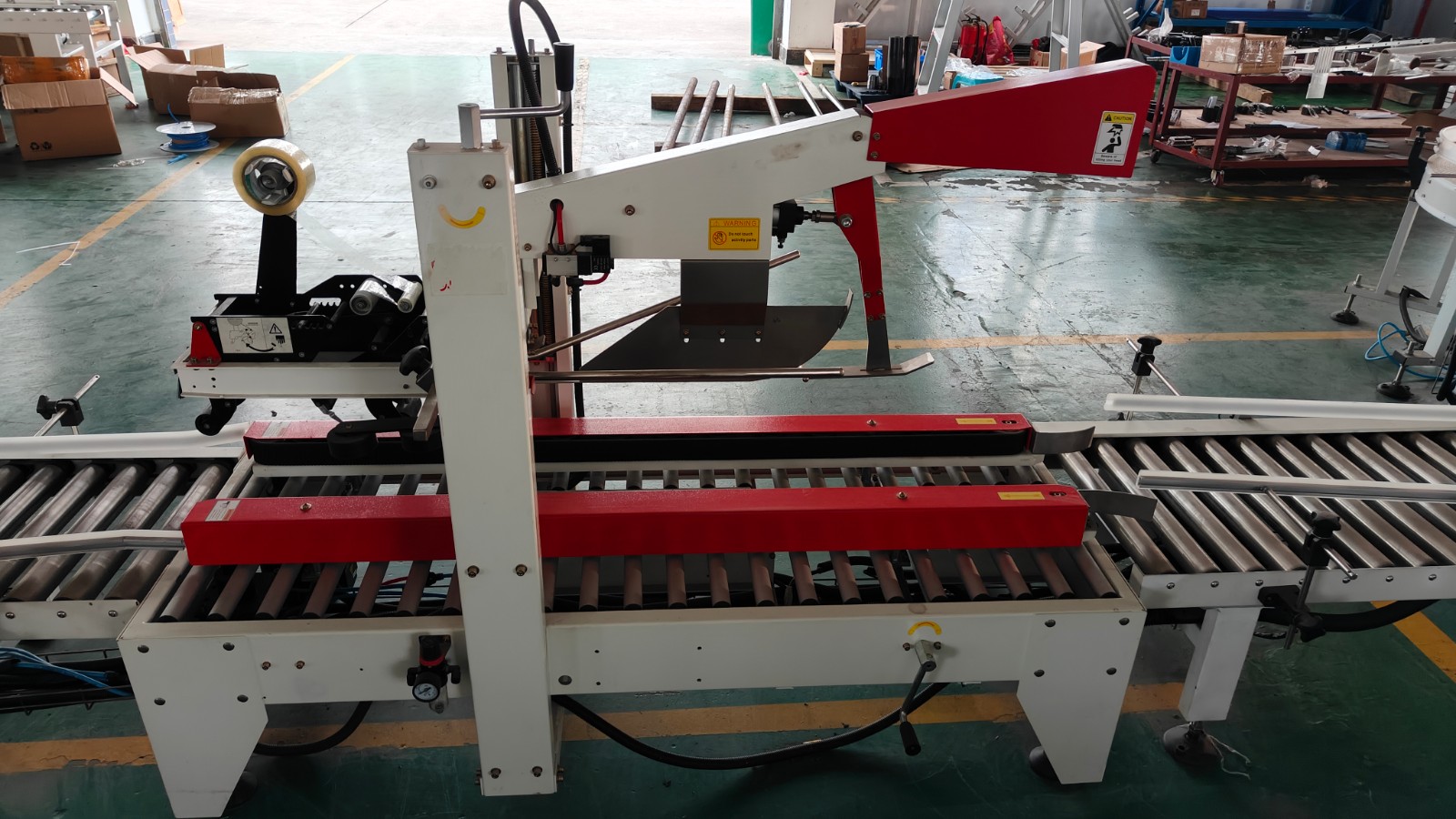

The BP-CS-ZG-18 automatic folding and carton sealing machine automatically folds the upper cover and automatically applies tape up and down, eliminating the need for manual work. It uses instant tape to seal the carton, which not only has a beautiful sealing effect, but also has a firm seal. It is equipped with an automated packaging assembly line. Use will better reflect the value of this machine. This carton sealing machine can be widely used in food, medicine, beverages, hardware and electronics, daily chemicals, catering, household paper, personal hygiene care products and other industries

Automatic Folding Carton Sealing Machine

The BP-CS-ZG-18 automatic folding and carton sealing machine automatically folds the upper cover and automatically applies tape up and down, eliminating the need for manual work. It uses instant tape to seal the carton, which not only has a beautiful sealing effect, but also has a firm seal. It is equipped with an automated packaging assembly line. Use will better reflect the value of this machine. This carton sealing machine can be widely used in food, medicine, beverages, hardware and electronics, daily chemicals, catering, household paper, personal hygiene care products and other industries

Product Specifications:

| Basic features | describe | Remark |

| Machine weight | 620kg | |

| Carton material | ≥5 layers of corrugated paper | Cartons need to be creased |

| Unboxing speed | 8-25 boxes/minute | |

| Robot payload | 5kg | |

| Control System | WARSONCO | |

| Pneumatic system | Standard AirTAC AirTAC | Optional |

Air source requirements | 0.4-0.8Mpa | |

| communication method | EtherCAT | |

| Material | Main frame: Q235 paint (off-white) | |

| ambient temperature | -5-45℃ | |

| ambient relative humidity | ≤75% (no condensation) | |

| Rated voltage | 220V | |

| Total power | 2.5KW | |

| Equipment noise | ≤80db | |

| Equipment area | L2685*W2260*H1500mm | |

| IP rating | IP54 | |

| Applicable tape width | W48, W60, W75 | |

| Countertop height | 650mm | |

| Air consumption | >500L/min | |

| Applicable carton size | L(200-500)mm W(120--400)mm H(120-350)mm | L+W<920mm, 1/2W+H<550mm |

The process of fully automatic carton sealing machine.

1. Preparation work: Before starting to operate the fully automatic carton sealing machine, you first need to prepare the boxes and packaging materials.

Boxes should be selected according to specified size and quality requirements to ensure the safety and stability of the packaging.

Packaging materials generally include tape, cardboard, etc., used to secure boxes and protect products.

2. Drop the box: Place the box on the workbench of the automatic carton sealing machine and ensure that the box is in the correct position.

Then, through automatic sensing devices or manual operation, the machine can identify the location and size of the box.

The machine automatically adjusts according to the size of the box to ensure the accuracy and stability of sealing.

3. Sealing: After the box is dropped, the fully automatic sealing machine automatically starts the sealing process.

The main processes of sealing are tape stretching, tape cutting and tape fixing.

The machine will stretch the tape from the reel to the appropriate length and stick it on the box according to pre-set parameters.

The tape cutting device then cuts the tape to the appropriate length and stores the remaining tape.

Tape fasteners will secure the tape to the box to ensure a secure seal.

4. Safety detection: The fully automatic carton sealing machine is also equipped with a safety detection device during the carton sealing process to detect the sealing quality and equipment status.

Once an abnormality is detected, such as the tape not sticking, the tape tension being too high, or equipment failure, etc., the machine will automatically stop working and issue an alarm to remind the operator to handle it in time.

5. Box discharging: After completing the sealing, the fully automatic sealing machine will push the sealed boxes out of the machine to prepare for the next step of packaging and transportation.