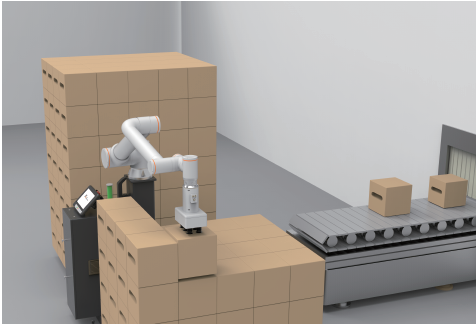

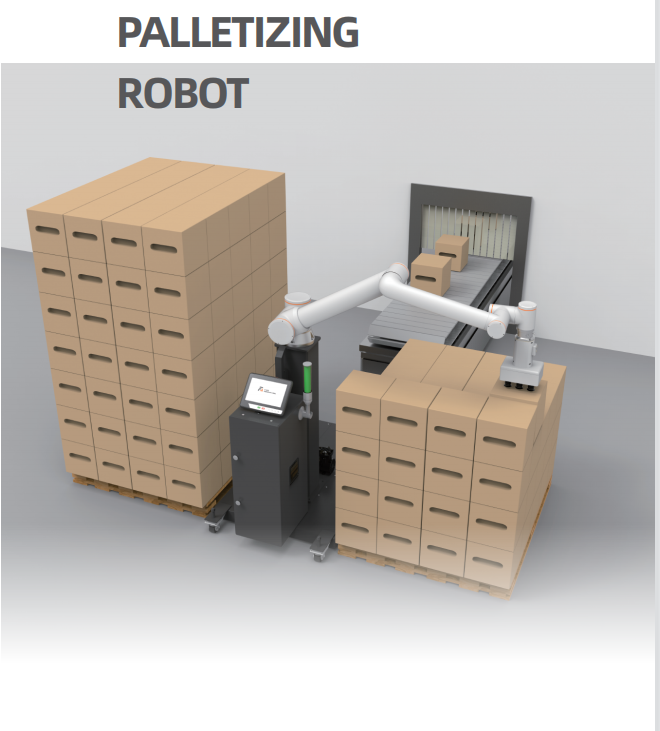

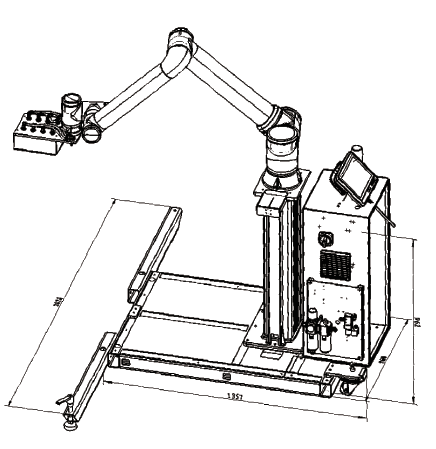

Fully Automatic Palletizing Robot

- backpack

- china guangdong foshan

- 2024

- 1000

✓ No need to add sensors.

✓ Easy to operate and simple to program

Can be used with a pallet jack or forklift

End execution tool configuration:

✓ Standard vacuum holder

✓ Common standard end holders

✓ Customized end clamping tooling (special items)

Fully Automatic Palletizing Robot

✓ No need to add sensors.

✓ Easy to operate and simple to program

Can be used with a pallet jack or forklift

End execution tool configuration:

✓ Standard vacuum holder

✓ Common standard end holders

✓ Customized end clamping tooling (special items)

Product Specifications:

| Gas source | 0.5-0.8Mpa (vacuum generator) |

| Air consumption | 350-450nl/min |

| power supply | 220VAC 50Hz ±10% |

| Maximum power consumption | 5KW |

| Total equipment weight | ≈350kg |

| Adapt to carton size | Can be based on user requirements |

| Stacking method | Can be based on user requirements |

| Maximum stack height* | The maximum stacking height that can be lifted and lowered is 2100mm (including pallets); generally up to 1600mm (including pallets) |

| Maximum pallet size* | 1200mm×1200mm |

| Stackable box dimensions* | L(260-500)mm*W(200-450) |

| Maximum allowable load | 20kg |

| Fastest stack speed | Stacking up to 8 boxes per minute |

| working radius | Maximum working radius 1600mm |

| security function | Optional: safety grating, safety fence, safety induction carpet |

| IP rating | The robot arm is IP54, the gripper and other accessories are IP32 compliant |

| interface | Supports multiple safety inputs and outputs, including emergency stop, safety protection, administrator mode, and factory setting mode |

| security function | Emergency stop function, reserved external safety interface (can be controlled through I/O interface) |

| Indicator status | When powered on normally, the indicator light is always green; when powered off, the indicator light goes out. |

Simple palletizing software

Easy Palletizing software eliminates the need for advanced robot programming. It only requires the user to enter 3 sets of key information:

Carton box size (i.e. width x length x height); pallet size: pallet width, pallet length, pallet height, box stacking height; conveyor size:

Conveyor height, conveyor positioning indicator (sensor on palletizer to verify conveyor is positioned in place, screen

displays a red or green indicator light), with this information, the system will automatically calculate and direct the robot's movement.

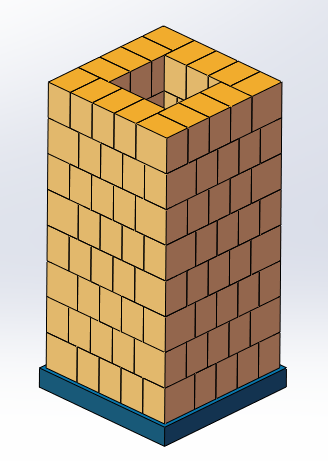

Size range of palletized objects

Length 1200

Width 1200

Height 2550

A palletizing robot is an automated equipment used to stack products together in a certain order and manner. They are commonly used in logistics, warehousing and packaging aspects of industrial production. The following is how to use a palletizing robot:

1. Material preparation: Before using the palletizing robot, the materials need to be prepared. This includes checking whether the box markings and specifications meet the requirements, checking whether the materials are within the shelf life, and whether they are stored in a dry, oil-free, and dust-free environment.

2. Pre-operation inspection: Before starting to operate the palletizing robot, it is necessary to check whether the foundation of the mother pallet is firm and whether the pallet is clean, free of oil stains, and free of wear.

3. Turn on the robot: Follow the operating manual provided by the manufacturer to turn on the palletizing robot. Make sure all cables and power are connected.

4. Set the program: Set the program of the palletizing robot according to the size of the products and pallets that need to be stacked. This usually involves setting parameters such as the height, width and depth of the product the robot will grab.

5. Start the operation: Place the product in the working area of the palletizing robot, and then press the start button. Palletizing robots automatically grab and stack products on pallets.

6. Monitoring operations: During the operation of the palletizing robot, operators need to closely monitor the operation of the equipment. If any abnormality is found, press the emergency stop button immediately and notify maintenance personnel for inspection and repair.

7. Complete the operation: When the palletizing robot completes the operation, the operator needs to remove the pallet from the work area and put the new pallet into the work area to prepare for the next operation.

8. Shut down the robot: After completing all operations, shut down the palletizing robot according to the instructions in the operation manual, and ensure that all power supplies and connecting wires are disconnected.