Collaborative Robot Fully Automatic Carton Unpacking Machine

- backpack

- foshan

- 2024

- 1000+

1. The BP-CE-25XL collaborative robot automatic carton unpacking machine is a product independently developed and produced by our company. The unpacking speed reaches 15-25 boxes/minute, which is much faster and more economical than the vertical carton unpacking machine of the same level. . This unpacking machine has been widely used in many industries such as food, medicine, beverages, tobacco, daily chemicals, electronics, household paper, and personal hygiene care products.

Working speed: 5-25 boxes/minute

Total power: 2.5KW

Adaptation range:

L (200-500) mm

W(120--400)mm

H(120-350)mm

L+W<920mm, 1/2W+H<550mm

The BP-CE-25XL collaborative robot automatic carton unpacking machine is a product independently developed and produced by our company. The unpacking speed reaches 15-25 boxes/minute, which is much faster and more economical than the vertical carton unpacking machine of the same level. . This unpacking machine has been widely used in many industries such as food, medicine, beverages, tobacco, daily chemicals, electronics, household paper, and personal hygiene care products.

The complete machine components include: collaborative robot body, human-machine control interface, cardboard storage trough, material rack width adjustment, pressure plate height adjustment, cardboard suction cup assembly, output carton belt width adjustment, carton bottom forming mechanism, bottom sealing mechanism, Carbon steel painted body, pneumatic and electrical control systems, etc.

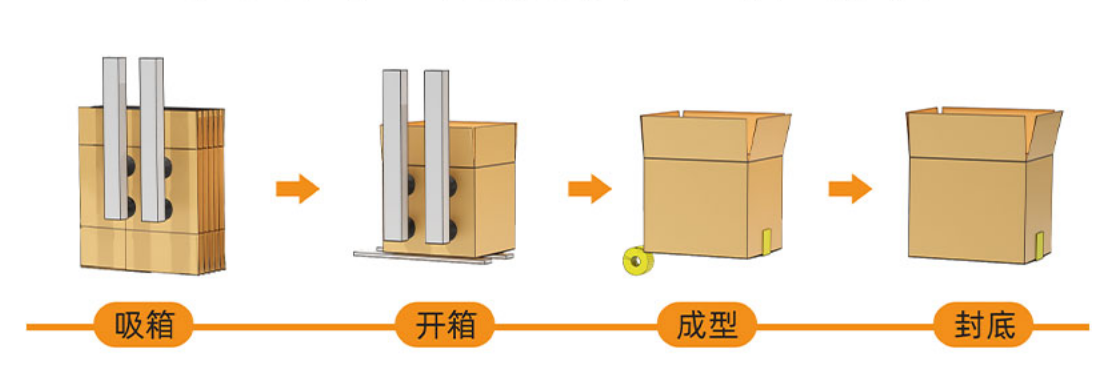

The action of this carton unpacking machine is to integrate carton taking, forming, folding and back sealing. First, place the flat carton on the storage trough (about 100 cartons can be stored, depending on the thickness of the cardboard). Use the suction cup to suck the carton out of the trough. Shape the carton while sucking it out, and then fold it forward and backward. Cover the left and right sides, and finally complete the tape sealing.

The entire action of the equipment is completed automatically, the operation is simple, and it is controlled by P.L.C + touch screen.

It is equipped with a safety device that alarms in advance for material shortage and automatically shuts down when there is no material.

The equipment has strong applicability and can be suitable for different carton sizes. It only takes 5 minutes to adjust, which is efficient and convenient.

The overall material is made of Q235 carbon steel paint to ensure the hygienic level of the equipment, clean and hygienic.

It can be operated as a stand-alone machine or used in conjunction with automated packaging lines.

Product Specifications:

| Basic features | describe | Remark |

| Machine weight | 620kg | |

| Carton material | ≥5 layers of corrugated paper | Cartons need to be creased |

| Unboxing speed | 8-25 boxes/minute | |

| Robot payload | 5kg | |

| Control System | WARSONCO | |

| Pneumatic system | Standard AirTAC AirTAC | Optional |

| Air source requirements | 0.4-0.8Mpa | |

| communication method | EtherCAT | |

| Material | Main frame: Q235 paint (off-white) | |

| ambient temperature | -5-45℃ | |

| ambient relative humidity | ≤75% (no condensation) | |

| Rated voltage | 220V | |

| Total power | 2.5KW | |

| Equipment noise | ≤80db | |

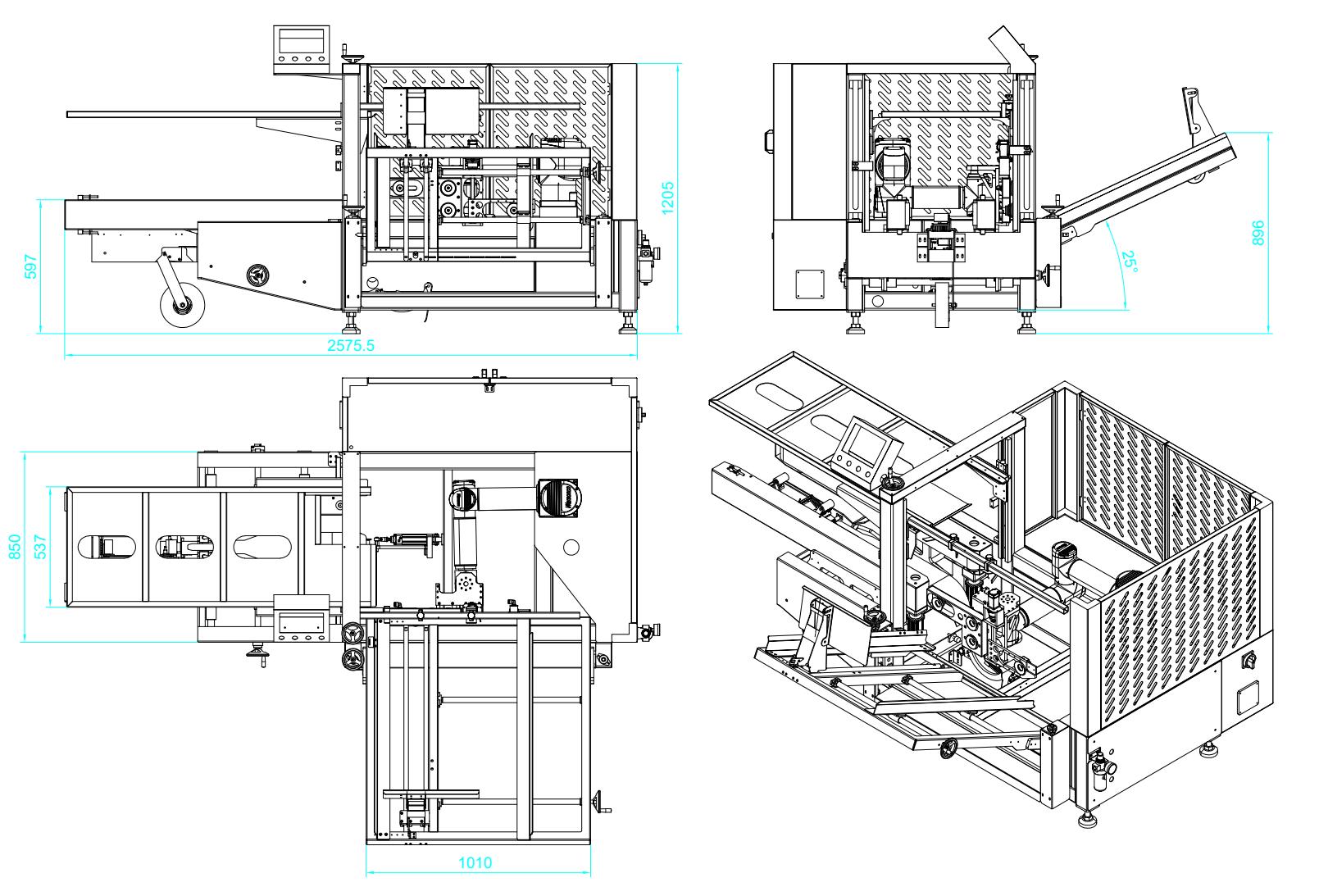

| Equipment area | L2685*W2260*H1500mm | |

| IP rating | IP54 | |

| Applicable tape width | W48, W60, W75 | |

| Countertop height | 650mm | |

| Air consumption | >500L/min | |

Applicable carton size | L(200--500)mm W(120--400)mm H(120--350)mm | L+W<920mm 1/2W+H<550mm |