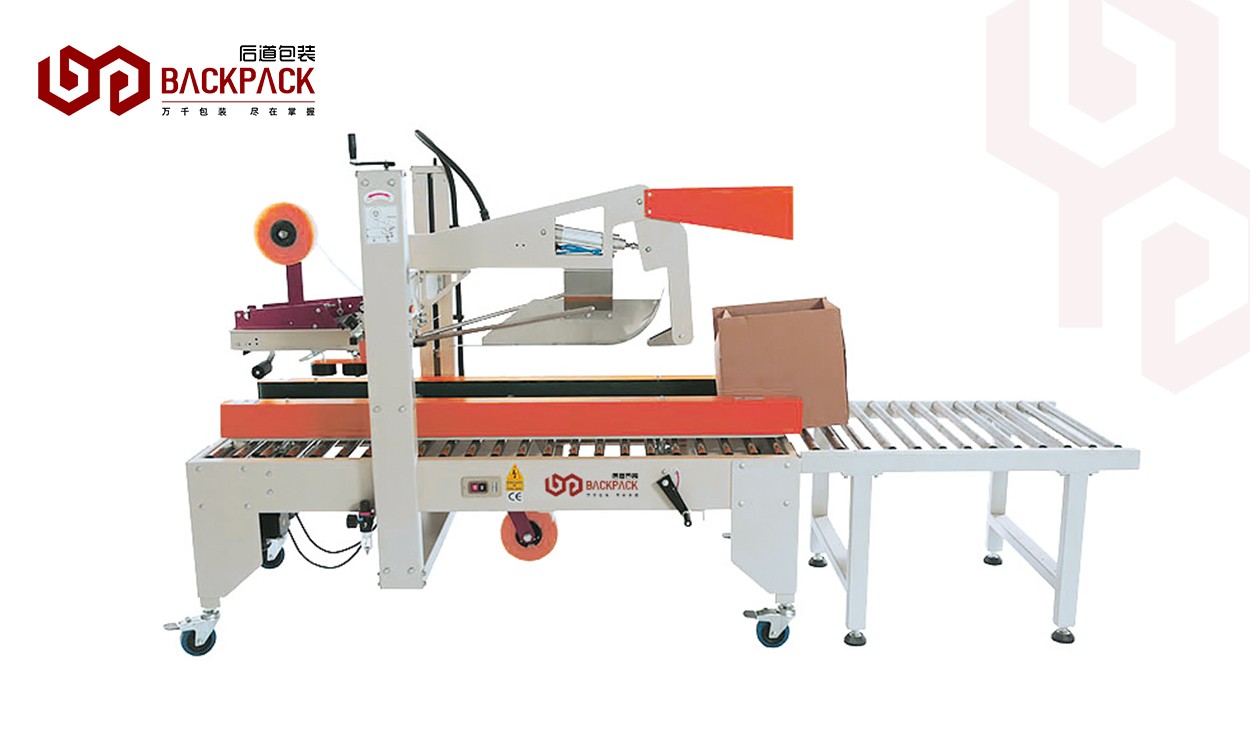

Sealing machine

Automatic folding and sealing machine is a mechanical equipment widely used in the packaging industry, mainly used for automatic operations such as folding, sealing, and sealing. The working principle of an automatic folding and sealing machine is to transport cardboard boxes along a production line to different workstations, and then use components such as mechanical arms, suction cups, and cylinders to achieve automatic folding, sealing, and bottom sealing of the cardboard boxes, ultimately achieving a fast and efficient sealing production process.

The workflow of an automatic folding and sealing machine usually includes the following steps:

Pre processing: feeding fixed length cardboard into the system for subsequent processing and making cardboard boxes.

Carton feeding: The cardboard boxes are pushed to the positioning position by automatic feeding equipment to ensure the correctness of subsequent processing.

Automatic flip: Use a robotic arm or suction cup to flip the cover back and display it in an open area.

Sealing the bottom of the box: Automatic sealing and sealing operations are carried out in the area at the bottom of the box.

Automatic capping: Flip the cover back and switch it in place, then perform the automatic capping operation.

Discharge point: Push the sealed cardboard box to the next production line and proceed to the next workflow.

The application range of automatic folding and sealing machines is very wide, including various industries such as food, beverage, medicine, electronics, and daily necessities. At present, the advantages of automatic folding and sealing machines in the packaging field are mainly reflected in the following aspects:

Improving production efficiency: The use of automatic folding and sealing machines can greatly improve production efficiency, enhance the operational efficiency of individual workers, and thus reduce production costs.

Reducing labor costs: Automating the sealing operation can save labor costs, reduce manual labor intensity in production, and create a safer and healthier working environment.

Higher precision: The automatic folding and sealing machine can ensure the accuracy and consistency of each sealing operation, ensuring the consistency and quality of the product.

Reduce errors: The automatic folding and sealing machine can reduce errors and defects during manual operation, and improve the overall quality and stability of the product.

In summary, automatic folding and sealing machines are playing an increasingly important role in the modern packaging industry. Their automated processing can reduce labor costs, improve production efficiency, improve product quality and stability, and will gradually replace manual operation as an inevitable trend in the future.

Technical parameters of automatic folding and sealing machine

Conveying speed: 0-20m/min

Maximum packaging size: L500 x W500 x H500mm

Minimum packaging size: L200 x W150 x H150mm

Power supply: 220/380V, 1 ф- three ф、 50/60Hz

Consumption function: 240W

Applicable tape: W48mm/60mm/75mm, choose one to use

Machine size: L1700 x W880 x H1450mm (excluding front and rear drum frames)

Machine weight: 280kg